Security Guard and Energy Steward of Electronic Systems

In today's highly electronic era, circuit protection and power management are like two solid pillars of an electronic system. The former is like a loyal guard, always alert to various abnormal situations that may occur in the circuit to ensure that the system is protected from electrical hazards. The latter is like a fine housekeeper, carefully regulating the distribution and conversion of electrical energy to provide just the right energy support for the stable operation of the system. From tiny handheld electronic devices to huge industrial control systems, from daily household appliances to cutting-edge scientific research instruments, circuit protection and power management components are quietly working behind the scenes, escorting the vigorous development of electronic technology and profoundly affecting all aspects of modern life.

Circuit protection components, as the first line of defense of an electronic system, are responsible for preventing system damage due to electrical failures such as overvoltage, overcurrent, and electrostatic discharge (ESD). There are many types of them, each of which is specific to specific electrical hazards and has a unique protection mechanism.

Varistors are the best at dealing with overvoltage. Their resistance value will change significantly with the change of voltage at both ends. When there is an instantaneous high voltage spike in the circuit, such as the instantaneous surge voltage generated by the lightning strike induced voltage\ power switch, the resistance value of the varistor will decrease sharply, shunting the surge current to the ground, thus limiting the voltage rise at both ends of the protected circuit and protecting it from the impact of high voltage. Varistors often appear in the power input terminal\ communication line interface and other parts of electronic equipment, effectively protecting the internal sensitive electronic components, such as integrated circuits\ transistors, etc., from being damaged by high voltage breakdown. For example, in a computer power supply, a varistor can absorb the surge voltage from the power grid, ensuring that the computer can still operate safely in thunderstorms or unstable power grids; in the signal transmission line of a communication base station, a varistor can prevent damage to communication equipment due to lightning induction or line failure.

The transient suppression diode (TVS) focuses on the suppression of fast transient voltages. It can respond to overvoltages in a very short time (picosecond to nanosecond), clamp the excessive voltage at a safe level, and quickly release the surge energy to the ground. TVS diodes have the advantages of fast response speed, accurate clamping voltage, and large power capacity, and are widely used in circuits that are sensitive to voltage and require fast protection, such as computer interface circuits, high-speed data transmission lines, and sensors and Control Units in automotive electronic systems. In the computer's USB interface circuit, TVS diodes can effectively prevent damage to the interface chip and connected external devices due to instantaneous high voltage generated by hot-swapping or external electrostatic discharge; in automotive electronic systems, TVS diodes provide protection for various sensors and Control Units, ensuring that the car can still operate normally in complex electromagnetic environments and electrical disturbances, improving the safety and reliability of the car.

In addition to the above-mentioned common circuit protection components, gas discharge tubes and self-recovery fuses also play an important role in different application scenarios. Gas discharge tubes perform well in high-voltage and high-current overvoltage protection situations, such as high-voltage power line protection of communication base stations; self-recovery fuses have the characteristics of automatically restoring the conduction state after troubleshooting, and are suitable for some circuits that need to avoid frequent replacement of fuses, such as motor overload protection circuits.

Power management, as the energy hub of an electronic system, is responsible for the conversion, distribution, and regulation of electrical energy to meet the diverse power requirements of various modules in the system. It covers a wide range of content, from simple linear voltage regulation to efficient switching power supplies, from battery charging management to complex power monitoring and distribution systems, each link has a profound impact on the overall performance and reliability of the electronic system.

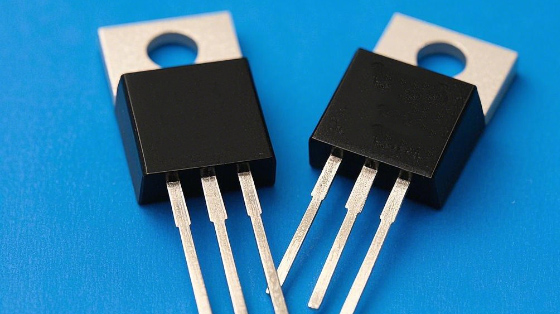

The linear voltage regulator is a traditional and relatively simple power management component. It keeps the output voltage constant by adjusting the conduction degree of the internal transistor. Its working principle is based on feedback control of the difference between the input voltage and the output voltage. When the input voltage changes or the load current fluctuates, the voltage regulator will adjust the transistor resistance accordingly to maintain the stability of the output voltage. The linear voltage regulator has the advantages of high output voltage accuracy, small ripple, and simple circuit. It is suitable for applications where power supply noise is low and power demand is small, such as some low-power microcontroller systems and the analog circuit part of precision measuring instruments. In a low-power sensor node, a linear regulator can provide a stable power supply for the sensor chip and microcontroller, ensuring that the sensor can accurately collect and transmit data. In the preamplifier circuit of an audio amplifier, a linear regulator can provide a low-noise power supply to avoid power ripple interfering with audio signals and ensure the purity of sound quality.

Switching power supplies occupy an important position in modern electronic devices due to their high efficiency and small size. They perform high-frequency chopping of the input DC or AC voltage by controlling the on-and-off time of the switch, and then perform voltage conversion and filtering through components such as transformers, rectifiers, and filters to finally obtain the required stable output voltage. The operating frequency of switching power supplies is usually higher, which makes it possible to use smaller transformers and filter components, thus achieving a miniaturized design. At the same time, due to the relatively low power consumption of switches in the on-and-off states, the overall efficiency of switching power supplies is much higher than that of linear regulators, especially suitable for applications requiring high power and high efficiency, such as computer power supplies, chargers, and communication base station power supplies. In a computer power supply, the switching power supply converts the mains power into a variety of DC voltages required by various components of the computer, such as + 12V to power the hard disk, optical drive, etc., + 5V and + 3.3V to power the main board, CPU, etc. Its high-efficiency characteristics help reduce the overall power consumption of the computer and reduce heat generation; in a fast charger, the switching power supply can automatically adjust the output voltage and current according to the charging state and demand of the battery to achieve a fast and safe charging process and meet people's requirements for the charging speed of mobile devices.

The battery charging management chip is a key component that is specifically designed to precisely control the battery charging process. It can intelligently adjust the charging current, voltage, and charging time according to the type of battery (such as lithium-ion battery, nickel-metal hydride battery, etc.), capacity, and current state to ensure that the battery is charged safely and efficiently. During the charging process, the charging management chip will monitor the battery's voltage, temperature, and other parameters in real time to prevent abnormal conditions such as battery overcharge and overtemperature. For example, in the charger of a smart phone, the charging management chip works in conjunction with the battery management system inside the phone, and according to the battery's power and health status, the appropriate charging mode is adopted, such as constant current charging, constant voltage charging, trickle charging, etc., which can not only charge the phone quickly, but also extend the battery life and ensure the safety of the phone.

In addition, power management also includes a power monitoring and distribution system, which can monitor various parameters of the power supply in real time, such as voltage, current, and power, and make reasonable power distribution according to the needs of the system. In large server systems, data centers, etc., power monitoring and distribution systems are particularly important. It can centrally manage and monitor multiple power modules. When a power module fails, it can be switched to a backup power module in time to ensure the uninterrupted operation of the entire system. At the same time, it can also dynamically adjust power distribution according to the load conditions of various components in the server, improve power utilization, and reduce energy consumption.

With the rapid development of electronic technology, circuit protection and power management components are also constantly innovating and evolving. In the research and development of new materials, new semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) are gradually applied in the field of circuit protection and power management. These wide-bandgap semiconductor materials have higher breakdown electric field strength, lower on-resistance, and better thermal conductivity, which can significantly improve the voltage resistance and power processing capabilities of circuit protection devices, while further improving the efficiency of switching power supplies. For example, power MOSFETs based on SiC or GaN can achieve higher switching frequencies and lower switching losses in switching power supplies, reducing heat dissipation requirements, providing strong support for the miniaturization and efficiency of power systems.

In terms of intelligence and integration trends, circuit protection and power management components are increasingly incorporating intelligent control functions and integrating multiple functions into one. Intelligent circuit protection devices can monitor the working status of circuits in real time, automatically adjust protection parameters, and even have self-diagnosis and early warning functions, improving the reliability and flexibility of circuit protection. For example, some smart fuses can not only blow quickly when overcurrent, but also send fault information to the host computer through the communication interface, which is convenient for remote monitoring and maintenance. Power management chips are also moving towards a highly integrated direction, integrating multiple functional modules, such as voltage regulation, charge management, and power monitoring, into a single chip, reducing the number of external components, reducing system cost and complexity, and improving system reliability and stability. In the smartphone chip, a power management unit (PMU) is integrated, which can provide accurate power supply and management for each functional module of the mobile phone, and at the same time realize functions such as charging control and power monitoring of the battery, which greatly simplifies the design of the main board of the mobile phone and improves the overall performance of the mobile phone.

Driven by the demand for new energy and energy conservation, circuit protection and power management are facing new opportunities and challenges in the fields of renewable energy power generation systems and electric vehicles. In solar photovoltaic power generation systems, the power management system needs to track the output of photovoltaic cells to the maximum power point (MPPT) to improve power generation efficiency; at the same time, circuit protection devices should be able to cope with the possible overvoltage/overcurrent of photovoltaic arrays to ensure the safe and stable operation of the system. In electric vehicles, the battery management system (BMS), as the core part of power management, requires accurate voltage and temperature monitoring and balanced management of a large number of battery cells to ensure the performance and safety of the battery pack; circuit protection devices should provide comprehensive protection for motor drive systems, charging systems, etc., to prevent safety accidents caused by electrical failures. In addition, with the increasing attention to energy conservation and environmental protection, the energy-saving optimization design of power management systems in various electronic devices has become increasingly important. By adopting advanced energy-saving technologies and control strategies, the standby power consumption and operating power consumption of electronic devices can be reduced, and energy efficiency can be achieved.